From basics to frontiers : a comprehensive review of plasma-modified and plasma-synthesized polymer films

– Authors : T. Dufour

– References : Polymers, Vol. 15, Issue 17, 3607, 54 pages (2023)

– Links : DOI, Free download

Abstract

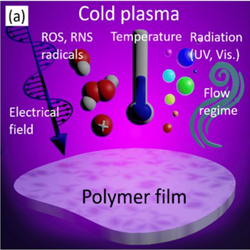

This comprehensive review begins by tracing the historical development and progress of cold plasma technology as an innovative approach to polymer engineering. The study emphasizes the versatility of cold plasma derived from a variety of sources including low-pressure glow discharges (e.g., radiofrequency capacitively coupled plasmas) and atmospheric pressure plasmas (e.g., dielectric barrier devices, piezoelectric plasmas). It critically examines key operational parameters such as reduced electric field, pressure, discharge type, gas type and flow rate, substrate temperature, gap, and how these variables affect the properties of the synthesized or modified polymers. This review also discusses the application of cold plasma in polymer surface modification, underscoring how changes in surface properties (e.g., wettability, adhesion, biocompatibility) can be achieved by controlling various surface processes (etching, roughening, crosslinking, functionalization, crystallinity). A detailed examination of Plasma-Enhanced Chemical Vapor Deposition (PECVD) reveals its efficacy in producing thin polymeric films from an array of precursors. Yasuda’s models, Rapid Step-Growth Polymerization (RSGP) and Competitive Ablation Polymerization (CAP), are explained as fundamental mechanisms underpinning plasma-assisted deposition and polymerization processes. Then, the wide array of applications of cold plasma technology is explored, from the biomedical field, where it is used in creating smart drug delivery systems and biodegradable polymer implants, to its role in enhancing the performance of membrane-based filtration systems crucial for water purification, gas separation, and energy production. It investigates the potential for improving the properties of bioplastics and the exciting prospects for developing self-healing materials using this technology.

Fuel cell electrodes from organometallic platinum precursors : an easy atmospheric plasma approach

– Authors : D. Merche, T. Dufour, J. Banneton, G. Caldarella, V. Debaille, N. Job, F. Reniers

– References : Plasma processes and polymers, 2016, Vol. 13, Issue 1, 91-104

– Links : DOI, HAL (free download)

Abstract

An organometallic powder (platinum (II) acetylacetonate) is decomposed in the post- discharge of an atmospheric RF plasma torch to deposit Pt nanoparticles on carbon black supports. The resulting nanohybrid materials are characterized by FEG-SEM and XPS techniques to highlight their high content in Pt, their oxidation degree, and the dispersion of the Pt nanoparticles on the substrate. ICP-MS and electrochemical characterizations in a single fuel cell (cyclic voltammetry, dynamic polarization curves) are also performed on electrodes realized by treating the powder mixture overlaid on gas diffusion layers. The comparison of the catalytic activity and the Pt loading with commercially available electrodes shows the great potential of this simple innovative, fast, and robust deposition method.

Synthesis and texturization processes of (super)-hydrophobic fluorinated surfaces by atmospheric plasma

– Authors : J. Hubert, J. Mertens, T. Dufour, N. Vandencasteele, F. Reniers, P. Viville, R. Lazzaroni, M. Raes, H. Terryn

– References : Journal of Materials Research, 2015, Vol. 30, Issue 21, 3177-3191

– Links : DOI, HAL (free download)

Abstract

The synthesis and texturization processes of fluorinated surfaces by means of atmospheric plasma are investigated and presented through an integrated study of both the plasma phase and the resulting material surface. Three methods enhancing the surface hydrophobicity up to the production of super-hydrophobic surfaces are evaluated: (i) the modification of a polytetrafluoroethylene (PTFE) surface, (ii) the plasma deposition of fluorinated coatings and (iii) the incorporation of nanoparticles into those fluorinated films. In all the approaches, the nature of the plasma gas appears to be a crucial parameter for the desired property. Although a higher etching of the PTFE surface can be obtained with a pure helium plasma, the texturization can only be created if O2 is added to the plasma, which simultaneously decreases the total etching. The deposition of CxFy films by a dielectric barrier discharge leads to hydrophobic coatings with water contact angles (WCAs) of 115°, but only the filamentary argon discharge induces higher WCAs. Finally, nanoparticles were deposited under the fluorinated layer to increase the surface roughness and therefore produce super-hydrophobic hybrid coatings characterized by the nonadherence of the water droplet at the surface.

Chemical and physical effects of the carrier gas on the atmospheric pressure PECVD of fluorinated precursors

– Authors : J. Hubert, N. Vandencasteele, J. Mertens, P. Viville, T. Dufour, C. Barroo, T. Visart de Bocarmé, R. Lazzaroni, F. Reniers

– References : Plasma Processes & Polymers, 2015, Vol. 12, Issue 10, 1174-1185

– Links : DOI, HAL (free download)

Abstract

The atmospheric pressure PECVD deposition and texturization of hydrophobic coatings using liquid fluorinated C6F12 and C6F14 precursors are investigated. The effect of the carrier gas (argon and helium) is discussed in terms of the behavior of the gas phase and of the characteristics of the deposited film. Mass spectrometry measurements indicate that the fragmentation is higher with argon while helium reacts very easily with oxygen impurities leading to the formation of CxFyOz compounds. These observations are consistent with the chemical composition of the films determined by XPS and the variation in the deposition rate. Moreover, the streamers present in the argon discharge affect the morphology of the surface by increasing the roughness, which leads to the increase in the hydrophobicity of the coatings

LDPE surface modifications induced by atmospheric plasma torches with linear and showerhead configurations

– Authors : S. Abou Rich, T. Dufour, P. Leroy, L. Nittler, J.-J. Pireaux, F. Reniers

– References : Plasma Processes & Polymers, 2015, Vol. 12, Issue 8, 771-785

– Links : DOI, HAL (free download)

Abstract

Low density polyethylene (LDPE) surfaces have been plasma-modified to improve their nanostructural and wettability properties. These modifications can significantly improve the deposition of subsequent layers such as films with specific barrier properties. For this purpose, we compare the treatments induced by two atmospheric plasma torches with different configurations (showerhead vs linear). The modifications of LDPE films in terms of chemical surface composition and surface morphology are evidenced by X-ray photoelectron spectroscopy, water contact angles measurements and atomic force microscopy. A comparison between the two post-discharge treatments is achieved for several torch-to-substrate distances (gaps), treatment times and oxygen flow rates in terms of etching rate, roughening rate, diffusion of oxygen into the subsurface and hydrophilicity. By correlating these results with the chemical composition of the post-discharges, we identify and compare the species which are responsible for the chemical surface functionalization, the surface roughening and etching.

Understanding polyethylene surface functionalization by an atmospheric He/O2 plasma through combined experiments and simulations

– Authors : T. Dufour, J. Minnebo, S. Abou Rich, E. C. Neyts, A. Bogaerts, F. Reniers

– References : J. Phys. D : Appl. Phys., 2014, Vol. 47, Issue 22, 224007 (12 pp)

– Links : DOI, HAL (free download)

Abstract

High density polyethylene surfaces were exposed to the atmospheric post-discharge of a radiofrequency plasma torch supplied in helium and oxygen. Dynamic water contact angle measurements were performed to evaluate changes in surface hydrophilicity and angle resolved X-ray photoelectron spectroscopy was carried out to identify the functional groups responsible for wettability changes and to study their subsurface depth profiles, up to 9 nm in depth. The reactions leading to the formation of C–O, C=O and O–C=O groups were simulated by molecular dynamics. These simulations demonstrate that impinging oxygen atoms do not react immediately upon impact but rather remain at or close to the surface before eventually reacting. The simulations also explain the release of gaseous species in the ambient environment as well as the ejection of low molecular weight oxidized materials from the surface.

Effect of cationic and anionic surfactants on application of calcium carbonate nanoparticles in paper coating

– Authors : A. Barhoum, H. Rahier, R. Abouzeid, M. Rehan, T. Dufour, G. Hill, F. Reniers, A. Dufresne

– References : ACS Appl. Mater. Interfaces, 2014, Vol. 6, Issue 4, 2734-2744

– Links : DOI HAL (free download)

Abstract

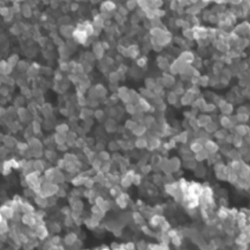

Modification of calcium carbonate particles with surfactant significantly improves the properties of the calcium carbonate coating on paper. In this study, unmodified and CTAB (hexadecyltetramethylammonium bromide)- and oleate-modified calcium carbonate nanoparticles were prepared using the wet carbonation technique for paper coating. CTAB (cationic surfactant) and sodium oleate (anionic surfactant) were used to modify the size, morphology, and surface properties of the precipitated nanoparticles. The obtained particles were characterized using X-ray diffraction (XRD), Fourier transform infrared (FT-IR) spectroscopy, zeta potential measurements, thermal gravimetric analysis (TGA), and transmission electron microscopy (TEM). Coating colors were formulated from the prepared unmodified and modified calcium carbonates and examined by creating a thin coating layer on reference paper. The effect of calcium carbonate particle size and surface modification on paper properties, such as coating thickness, coating weight, surface roughness, air permeability, brightness, whiteness, opacity, and hydrophobicity, were investigated and compared with commercial ground (GCC) calcium carbonate-coated papers. The results show that the obtained calcium carbonate nanoparticles are in the calcite phase. The morphology of the prepared calcium carbonate nanoparticles is rhombohedral, and the average particle diameter is less than 100 nm. Compared to commercial GCC, the use of unmodified and CTAB- and oleate-modified calcium carbonate nanoparticles in paper coating improves the properties of paper. The highest measured paper properties were observed for paper coated with oleate-modifed nanoparticles, where an increase in smoothness (decrease in paper roughness) (+23 %), brightness (+1.3 %), whiteness (+2.8 %), and opacity (+2.3 %) and a decrease in air permeability (-26 %) was obtained with 25% less coat weight. The water contact angle at a drop age time of 10 min was about 112° for the paper coated with oleate-modified nanoparticles and 42° for paper coated with CTAB-modified nanoparticles compared to 104° for GCC-coated paper.

In-depth diffusion of oxygen into LDPE exposed to an Ar-O2 atmospheric post-discharge : a complementary approach between ARXPS and Tof-SIMS

– Authors : S. Abou Rich, P. Leroy, T. Dufour, N. Wehbe, L. Houssiau, F. Reniers

– References : Surf. Interface Anal., 2014, Vol.46, Issue 3, 164-174

– Links : DOI, HAL (free download)

Abstract

The in-depth oxygen diffusion into a low density polyethylene film is performed in the post-discharge of an atmospheric plasma torch, supplied in argon as carrier gas and with or without oxygen as reactive gas. The chemical and structural properties of the polymer surface and bulk are studied in terms of plasma parameters (treatment time, power, and reactive gas flow rate). A good correlation between XPS and Fourier transform infrared spectroscopy analyses is demonstrated. The penetration depth of oxygen into the bulk of the polymer is investigated by angle resolved-XPS and time-of-flight SIMS. It is shown that, depending on the plasma conditions, oxygen could penetrate up to 20-40nm into the low density polyethylene during the atmospheric plasma treatment.

LDPE films treated by an atmospheric Ar-O2 post-discharge : functionalization, etching, degradation and partial recovery of the native wettability state

– Authors : S. Abou Rich, T. Dufour, P. Leroy, L. Nittler, J.-J. Pireaux, F. Reniers

– References : J. Phys. D : Appl. Phys., 2014, Vol. 47, Issue 6, 065203

– Links : DOI, HAL (free download)

Abstract

To optimize the adhesion of layers presenting strong barrier properties on low-density polyethylene (LDPE) surfaces, we investigated the influence of argon and argon-oxygen atmospheric pressure post-discharges. This study was performed using X-ray photoelectron spectroscopy, atomic force microscopy, optical emission spectroscopy (OES) and dynamic water contact angle (WCA) measurements. After the plasma treatment, a slight increase in the roughness was emphasized, more particularly for the samples treated in a post-discharge supplied in oxygen. Measurements of the surface roughness and of the oxygen surface concentration suggested the competition of two processes playing a role on the surface hydrophilicity and occurring during the post-discharge treatment: the etching and the activation of the surface. The etching rate was estimated to about 2.7 nm.s−1 and 5.8 nm.s−1 for Ar and Ar-O2 post-discharges, respectively. The mechanisms underlying this etching were investigated through experiments, in which we discuss the influence of the O2 flow rate and the distance (gap) separating the plasma torch from the LDPE surface located downstream. O atoms and NO molecules (emitting in the UV range) detected by OES seem to be good candidates to explain the etching process. An ageing study is also presented to evidence the stability of the treated surfaces over 60 days. After 60 days of storage, we showed that whatever the O2 flow rate, the treated films registered a loss of their hydrophilic state since their WCA increased towards a common threshold of 80°. This ‘hydrophobic recovery’ effect was mostly attributed to the reorientation of induced polar chemical groups into the bulk of the material. Indeed, the relative concentrations of the carbonyl and carboxyl groups at the surface decreased with the storage time and seemed to reach a plateau after 30 days.

Competitive and synergistic effects between excimer VUV radiation and O radicals on the etching mechanisms of polyethylene and fluoropolymer surfaces treated by an atmospheric He-O2 post-discharge

– Authors : T. Dufour, J. Hubert, N. Vandencasteele, P. Viville, R. Lazzaroni, F. Reniers

– References : J. Phys. D : Appl. Phys., 2013, Vol. 46, Issue 31, 315203 (14 pp)

– Links : DOI, HAL (free download)

Abstract

Among various surface modification techniques, plasma can be used as a source for tailoring the surface properties of diverse materials. HDPE and fluoropolymer surfaces have been treated by the post-discharge of an atmospheric RF-plasma torch supplied with helium and oxygen gases. The plasma-treated surfaces were characterized by measurements of mass losses, water contact angles, x-ray photoelectron spectroscopy and atomic force microscopy. This experimental approach correlated with an optical characterization of the plasma phase allowed us to propose etching mechanisms occurring at the post-discharge/polymer interface. We discuss how competitive and synergistic effects can result from the oxidation and/or the roughening of the surface but also from the excimer VUV radiation, the He metastable species and the O radicals reaching the plasma-polymer interface.

PTFE surface etching in the afterglow of a scanning RF plasma torch : evidence of ejected fluorinated species

– Authors : T. Dufour, J. Hubert, P. Viville, C. Duluard, S. Desbief, R. Lazzaroni, F. Reniers

– References : Plasma Processes and Polymers, 2012, Vol. 9, Issue 8, 820-829

– Links : DOI, HAL (free download)

Abstract

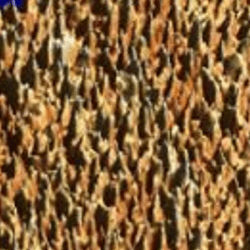

The texturization of poly(tetrafluoroethylene) (PTFE) surfaces is achieved at atmospheric pressure by using the post-discharge of a radio-frequency plasma torch supplied in helium and oxygen gases. The surface properties are characterized by contact angle measurement, X-ray photoelectron spectroscopy and atomic force microscopy. We show that the plasma treatment increases the surface hydrophobicity (with water contact angles increasing from 115° to 155°) only by modifying the PTFE surface morphology and not the stoichiometry. Measurements of sample mass losses correlated to the ejection of CF2 fragments from the PTFE surface evidenced an etching mechanism at atmospheric pressure.

Etching processes of polytetrafluoroethylene surfaces exposed to He and He-O2 atmospheric post-discharges

– Authors : J. Hubert, T. Dufour, N. Vandencasteele, S. Desbief, R. Lazzaroni, F. Reniers

– References : Langmuir, 2012, Vol. 28, Issue 25, 9466-9474

– Links : DOI, HAL (free download)

Abstract

A comparative study of polytetrafluoroethylene (PTFE) surfaces treated by the post-discharge of He and He-O2 plasmas at atmospheric pressure is presented. The characterization of treated PTFE surfaces and the species involved in the surface modification are related. In pure He plasmas, no significant change of the surface has been observed by X-ray photoelectron spectroscopy (XPS), dynamic water contact angles (dWCA) and atomic force microscopy (AFM), in spite of important mass losses recorded. According to these observations, a layer-by-layer physical etching without any preferential orientation is proposed, where the highly energetic helium metastables are the main species responsible for the scission of −(CF2)n− chains. In He-O2 plasmas, as the density of helium metastables decreases as a function of the oxygen flow rate, the treatment leads to fewer species ejected from the PTFE surfaces (in agreement with mass loss measurements and the detection of fluorinated species onto aluminum foil). However, the dWCA and AFM measurements show an increase in the hydrophobicity and the roughness of the surface. The observed alveolar structures are assumed to be caused by an anisotropic etching where the oxygen atoms etch mainly the amorphous

phase.

Synthesis of Membrane-Electrode Assembly for Fuel Cells by Means of (Sub)-Atmospheric Plasma Processes

– Authors : D. Merche, T. Dufour, J. Hubert, C. Poleunis, S. Yunus, A. Delcorte, P. Bertrand, F. Reniers

– References : Plasma Processes & Polymers, 2012, Vol. 9, Issue 11-12, 1144-1153

– Links : DOI, HAL (free download)

Abstract

An easy procedure to build up membrane-electrode assemblies for applications dedicated to miniaturized PEMFC using H2 or CH3OH by a two-steps atmospheric plasma process is reported. Firstly, catalyst nanoparticles are grafted on carbon substrates by spraying a Pt colloidal solution in the post-discharge of an RF atmospheric plasma torch. In the second step, the resulting decorated electrodes are covered by plasma synthesized polymeric membranes in the discharge of a DBD. The sulfonated polystyrene membranes are synthesized by injecting simultaneously styrene and trifluoromethanesulfonic acid monomers, in the presence of a carrier gas (Ar or He). The membranes are chemically characterized by XPS, ToF-SIMS, and FTIR (IRRAS) and their deposition rate is investigated by SEM.

Gas sensing properties of multiwall carbon nanotubes decorated with rhodium nanoparticles

– Authors : R. Leghrib, T. Dufour, F. Demoisson, N. Claessens, F. Reniers, E. Llobet

– References : Sensors and actuators B : Chemical, 2011, Vol. 160, Issue 1, 974-980

– Links : DOI, HAL (free download)

Abstract

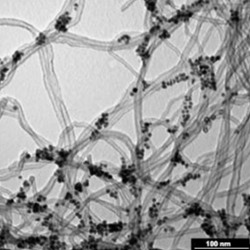

In the present work, multiwalled carbon nanotubes were decorated with rhodium nanoparticles using a colloidal solution in the post-discharge of an RF atmospheric plasma of argon (Ar) or argon/oxygen (Ar:O2). The properties of these hybrid materials towards the room temperature detection of NO2, C2H4, CO, C6H6 and moisture were investigated and discussed in view of compositional and morphological studies. It was found that the presence of oxygen in the plasma treatment is essential to significantly enhance the gas response of Rh-decorated multiwalled carbon nanotubes and to avoid response saturation even at low gas/vapor concentrations. These desirable effects are attributed to the presence of oxygen during the CNT plasma treatment since oxygenated vacancies act both as active adsorption sites for gases and as anchoring sites for Rh nanoparticles (the presence of Rh nanoclusters is nearly doubled in Ar:O2 treated samples as compared to Ar treated samples). The oxygen treatment also makes easier the charge transfer between Rh nanoparticles and carbon nanotubes upon gas adsorption. The method for treating and decorating multiwalled carbon nanotubes used here is simple, fast and scalable for producing gas sensitive nanohybrid materials with uniform and well-controlled properties.

Carbon nanotubes decorated with Au, Pt and Rh clusters by injection of colloidal solutions into the post-discharge of an RF atmospheric plasma

– Authors : N. Claessens, F. Demoisson, T. Dufour, A. Mansour, A. Felten, J. Guillot, J-J Pireaux, F Reniers

– References : Nanotechnology, 2010, Vol. 21, Issue 38, 385603

– Links : DOI, HAL (free download)

Abstract

In this paper, we present a new, simple, robust and efficient technique to decorate multi-wall carbon nanotubes (MWCNT) with metal nanoparticles. As case studies, Au, Pt and Rh nanoparticles are grafted onto MWCNTs by spraying a colloidal solution into the post-discharge of an atmospheric argon or argon/oxygen RF plasma. The method that we introduce here is different from those usually described in the literature, since the treatment is operated at atmospheric pressure, allowing the realization in only one step of the surface activation and the deposition processes. We demonstrate experimentally that the addition of oxygen gas in the plasma increases significantly the amount of grafted metal nanoparticles. Moreover, TEM pictures clearly show that the grafted nanoparticles are well controlled in size.